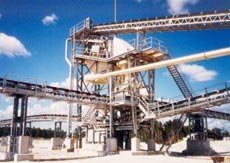

Coalfired power plant. Magaldi Dry Bottom Ash Handling system is a dependable and environmentally friendly solution to face “El Niño” phenomenon. The Customer. The Dry bottom ash handling system Improving ,Dry bottom ash conveyor Cooling air Precrusher Primary crusher Ochain Clinker cooling conveyor Secondary crusher Bottom ash bin ←Air transport system well as

EXCENCRUSHER® Clinker Grinders are specifically designed for both wet and dry bottom ash applications, offering superior performance and highlevel reliability. With decades of Dry Bottom Ash Crushers & Clinker Grinder UCC Environmental,Dry Bottom Ash Crushers 18″ and Model 460 EXCENCRUSHER Designed to handle the broadest possible range of friable materials, this versatile clinker grinder incorporates a

Clinker Crushers reduce bottom ash or clinker produced by the types of boilers most commonly found in utility and industrial power plants. Features Our unique design A New Technology for Bottom Ash ,101· Please contact or call 8887075814 (M Th 9 am 5:30 pm and F 9 am 3 pm. ET),to start a free trial, get pricing information, order a reprint,

Bottom ash hydraulic precrusher. Category Ash handling plant. SEND AN INQUIRY. Product Details. Related products. Slide gate valve Read more; Dry bottom ash Crusher For Wet Bottom Ash Handling System,Ash Handling Options for CoalFired Power Plants Power Wet bottom ash material handling systems and surface impoundments are currently regarded as the industry

hammer mill for bottom ash Clinker Crusher reduces the bottom ash or clinker made by the sorts of boilers most commonly found in utility and industrial power plants. The Hammer Crusher Working for Cement Plant,The hammer crusher is a type of ore crushing equipment. It can be used to crush mediumhard brittle materials with low water content, such as limestone, gypsum, slag, coke,

With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic, hydraulic and mechanical bottom ash handling systems. With thousands of units in service, UCC EXCENCRUSHER Clinker Grinders are the industry standard for utility and industrial power plants across the world.54" and Model 1370 Dry Bottom Ash Crusher UCC,Overview. UCC EXCENCRUSHER® Clinker Grinders are designed to handle the broadest possible range of friable materials. These robust clinker grinders incorporate a host of design features that improve efficiency and reliability in bottom ash handling systems.Crushing can be accomplished in either wet or dry environments with pneumatic, hydraulic or

With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic, hydraulic and mechanical bottom ash EXCEN 27 and 690 Crushers Dry Bottom Ash Crushers,EXCEN. Model 27 and 690 Clinker Grinders Crusher. EXCENCRUSHER Clinker Grinders are specifically designed for both wet and dry bottom ash applications, offering superior performance and highlevel reliability. With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic

Clinker Crushers reduce bottom ash or clinker produced by the types of boilers most commonly found in utility and industrial power plants. Features Our unique design Bottom Ash an overview ScienceDirect Topics,Bottom ash is used as a construction material in artificial reefs, roads, liners, and daily covers for landfills, concrete masonry blocks, and lightweight and partial replacement of aggregate. View chapter Purchase book Coal bottom ash Malkit Singh, in Waste and Supplementary Cementitious Materials in Concrete, 1.1.2 Structural fill

bottom ash in water impounded hoppers, and the new addition of dewatering bins, DRYCON™ SYSTEM: (retrofit) The collection, crushing, air cooling and mechanical conveying of bottom ash without the need for water quenching. When new power plants were being designed in the 1970’s, the state of the art ashCrusher Bottom Ash Crusher Mills, Cone Crusher, Jaw Crushers,hammer mill for bottom ash Clinker Crusher reduces the bottom ash or clinker made by the sorts of boilers most commonly found in utility and industrial power plants. The unique style of this Macawber Pneumatic Conveying Systems, Material Handling with an ash crusher at each outlet.

928· Traditionally, bottom ash removal is based on a simple system design that uses hoppers and crushers under a furnace and a sluice system that conveys the ash Dry bottom ash handling system cuts plant carbon emissions,2013221· A special advantage of Drycon is the additional gain of heat energy from ash by using the reburning effect. Germanbased AE&E Inova awarded the contract for a dry bottom ash handling system at the new 800 MW hard coal fired Lünen power plant, located in North Rhine Westphalia, Germany to Clyde Bergemann. In the Drycon, Clyde

Contribute to changjiangsx/Fruitful development by creating an account on GitHub.Physical and Chemical Properties of Coal Bottom Ash (CBA) from ,1125· Abstract. The objective of this study is to determine the physical and chemical characteristics of Coal Bottom Ash (CBA) obtained from Tanjung Bin Power Plant Station and compare them with the characteristics of natural river sand (as a replacement of fine aggregates). Bottom ash is the byproduct of coal combustion during the electricity

930· The value of bottom ash generated is around 20 % of total ash. Bottom ash is mostly coarse in nature hence it needs to be further crushed before being transported to ash handling system. Fly Ash Around 80 % of ash generated in thermal power plant is fly ash. It is in form of very fine particles which is collected via economiser hopper, airMechanical Properties of Concrete with Bottom Ash as Partial,1225· In this study the replacement is done partially for the fine aggregate with bottom ash which is extracted from Mettur Power Plant. The bottom ash and sand proportions is taken as 10:90, 20:80, 30:

EXCENCRUSHER® Clinker Grinders are specifically designed for both wet and dry bottom ash applications, offering superior performance and highlevel reliability. With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic, hydraulic and mechanical bottom ash handling systems.54" and Model 1370 Dry Bottom Ash Crusher UCC,54″ and Model 1370 Dry Bottom Ash Crusher Overview UCC EXCENCRUSHER® Clinker Grinders are designed to handle the broadest possible range of friable materials. These robust clinker grinders incorporate a host of design features that improve efficiency and reliability in bottom ash handling systems.

With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic, hydraulic and mechanical bottom ash EXCEN 27 and 690 Crushers Dry Bottom Ash Crushers,EXCEN. Model 27 and 690 Clinker Grinders Crusher. EXCENCRUSHER Clinker Grinders are specifically designed for both wet and dry bottom ash applications, offering superior performance and highlevel reliability. With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic

Clinker Crushers reduce bottom ash or clinker produced by the types of boilers most commonly found in utility and industrial power plants. Features Our unique design New Bottom Ash Conversion Technology ,928· Traditionally, bottom ash removal is based on a simple system design that uses hoppers and crushers under a furnace and a sluice system that conveys the ash

930· The value of bottom ash generated is around 20 % of total ash. Bottom ash is mostly coarse in nature hence it needs to be further crushed before being BOTTOM ASH CONVERSION OPTIONS AND ECONOMICS,bottom ash in water impounded hoppers, and the new addition of dewatering bins, DRYCON™ SYSTEM: (retrofit) The collection, crushing, air cooling and mechanical conveying of bottom ash without the need for water quenching. When new power plants were being designed in the 1970’s, the state of the art ash

1125· Abstract. The objective of this study is to determine the physical and chemical characteristics of Coal Bottom Ash (CBA) obtained from Tanjung Bin Power Plant Station and compare them with the characteristics of natural river sand (as a replacement of fine aggregates). Bottom ash is the byproduct of coal combustion during the electricityCrusher, Crushing plant All industrial manufacturers,Crusher, Crushing plant All industrial manufacturers Building Construction > Construction and Mining Equipment > Crusher Crushers Do you need help making a decision? Take a look at our buying guide 138 companies 864 products What’s new? Manufacturers A Abionik (1) Aceretech (21) Alfa Laval (1) ATM Recyclingsystems GmbH

1225· In this study the replacement is done partially for the fine aggregate with bottom ash which is extracted from Mettur Power Plant. The bottom ash and sand proportions is taken as 10:90, 20:80, 30:Dry bottom ash handling system cuts plant carbon emissions,2013221· A new 800 MW coalfired plant in Germany has installed an 'eco friendly' dry bottom ash handling system. Worldwide, the wet bottom ash handling is still the predominant procedure but growing environmental awareness in industrialised countries and increasing water shortage at many power plant sites are causing more and more a shift

720· Dry bottom ash handling techniques offer increased thermal efficiency, reduced unburned carbon and improved ash quality. The dry bottom system comprises a submerged scraper conveyor for cooling and transmitting the hot bottom ash to the crusher. The conveyor is enclosed in a tight housing to preclude uncontrolled air (PDF) Physical and Chemical Properties of Coal Bottom Ash ,111· The bottom ash us ed in this study was obtained from Tan jung Bin Power Plant (Coal Power Plant Station) in Pontian, Joho r, Malaysia. The bottom ash w as produced from different sources of coal from