Jaw Crusher BB 600 Material feed size*: < 350 x 170 mm Final fineness*: < 6 mm Throughput*: 3500 kg/h Product details *depending on feed material and instrument Jaw Crusher an overview ScienceDirect Topics,The relationship between the frequency of operation and capacity of the jaw crusher can be seen in Figure 4.5. This figure is plotted for values of LT = 0.228 m, W = 1.2 m, LMIN =

the effect of feed size (as can be seen from the data in Table 1 ). for the effect of feed size on jaw crusher capacity Capacity, thI Size of Rose and feed, m Hersam, W, Fruitful® C Series™ jaw crushers Fruitful Outotec,Jaw crushers Features Fruitful® C Series™ jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The

226· Much of the data on which sizing/design curves and tables are based comes from operations involving those two very important types: gyratory and jaw Jaw Crusher BB 300 RETSCH efficiency and long service life,Download. The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 140 mm. Depending on the

Final fineness can range from less than .5 mm to 6 mm. Material feed size ranges can be less 40 mm to 350 mm. Laboratory jaw crushers can process hardness feed material What are the features of a jaw crusher? LinkedIn,2023412· Published Apr 12, 2023. + Follow. The features of a jaw crusher include a large feed opening, superior materialhandling capabilities, robust construction, a simple

61· The particle size distributions for the five feed sizes are shown in Fig. 1.Due to the allowance for over and undersize in the naming of particle size fractions, Jaw Crushers high quality and reliability from RETSCH,Jaw Crusher BB 600 Material feed size*: < 350 x 170 mm Final fineness*: < 6 mm Throughput*: 3500 kg/h Product details *depending on feed material and instrument configuration/settings . Jaw crusher fields of application A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials.

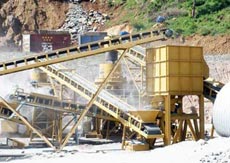

Fruitful® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.Jaw Crusher BB 600 XL Retsch Solutions in Milling & Sieving,Download. The Jaw Crusher BB 600 is specifically designed for accepting large feed sizes up to 350 x 170 mm. The gap width can be set stepless from 6 60 mm. Depending on the sample material, particle sizes down to 6 mm can be obtained in one working run, resulting in an excellent crushing ratio of 25. A throughput of up to 3500 kg/h is

Sizes: 6”x 10” through 20” x 30″ jaw opening Discharge size: ranges from 3/4” minus through 4″ minus Electric and gas power options are available All wear and replacement Laboratory Jaw Crusher Labcompare,Final fineness can range from less than .5 mm to 6 mm. Material feed size ranges can be less 40 mm to 350 mm. Laboratory jaw crushers can process hardness feed material ranges from mediumhard, hard, brittle, and tough. Products (1) User Reviews (1) Showing 1 of 1 products Company Filter Get Quote for All Zoom In

It can accept feed sizes up to 90 mm and has a stepless gap width adjustment from 030 mm. Depending on the sample material, it is capable of producing particle sizes down to 2 mm, resulting in a crushing ratio of 45. This versatile jaw crusher can be used in continuous pre and fine crushing processes, or in processline versions.The influence of feeder on the output capacity of jaw crusher,Therefore, strictly controlling the particle size of the raw materials is one of the most important prerequisites to ensure the normal operation of the jaw crusher. Practice has proved that when the maximum raw material particle size is 0.80.9 times the size of the feed inlet, the jaw breaker is not prone to jam and blockage. 2.

61· The particle size distributions for the five feed sizes are shown in Fig. 1.Due to the allowance for over and undersize in the naming of particle size fractions, the sizes d and D are not identical to the scalper slot widths.. Download : Download highres image (373KB) Download : Download fullsize image Fig. 1.Jaw Crushers Powerscreen,Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size. Powerscreen jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts. About.

2023410· Crushing Stage. Rock crushing consists of three stages: primary, secondary, and tertiary. In the primary phase, large pieces of rock get broken down into smaller sizes to be fed into other crushers to reduce their size even further. Largecapacity crushers that can handle more sizable feed materials are typically used in this stage.What are the features of a jaw crusher? LinkedIn,2023412· Published Apr 12, 2023. + Follow. The features of a jaw crusher include a large feed opening, superior materialhandling capabilities, robust construction, a simple design, and an additional

What size Jaw Crusher do I need? Use the following information to determine the Jaw Crusher size for your application: Maximum material lump or largest size expected to be crushed Tons per hour rate needing to be crushed Desired size of discharge material needed Operating hours per dayCrusher Close Side Settings Mineral ,117· The maximum feed size is approximately 8 0% of the feed opening. Open side setting (OSS) The open side setting is measured when the crusher is at rest. The

The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the feed characteristics (friction, gradation). WIDE TEETH (WT) For feed with a lot of fines; good wear resistance; can be used on both fixed and moving sides. SHARP TEETH (ST)Fruitful® C Series™ jaw crushers Proven reliability and,Fruitful® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

These crushers feature one to two tons (907 to 1,814kg) throughput per hour and are available powered by a gasoline or diesel engine, or an electric motor. Morse Jaw Crushers handle oversize feed and are available with 4x6in (102x152mm), 5x6in (127x152mm) and 8x8in (203x203mm) jaw sizes. Capacities include 400—1,200lb (182—545kg), 1,000—2Universal Jaw Crushers McLanahan,What size Jaw Crusher do I need? Use the following information to determine the Jaw Crusher size for your application: Maximum material lump or largest size expected to be crushed Tons per hour rate needing to be crushed Desired size of discharge material needed Operating hours per day

Download. The Jaw Crusher BB 100 is the smallest floor model of the series. It accepts feed sizes up to 50 mm. The gap width can be set stepless from 020 mm. Depending Jaw Crusher BB 600 XL Retsch Solutions in Milling & Sieving,Download. The Jaw Crusher BB 600 is specifically designed for accepting large feed sizes up to 350 x 170 mm. The gap width can be set stepless from 6 60 mm. Depending on the sample material, particle sizes down to 6 mm can be obtained in one working run, resulting in an excellent crushing ratio of 25. A throughput of up to 3500 kg/h is

Fruitful® C120™ jaw crusher is ideal for primary crushing Fruitful® C120™ jaw crusher is generally used as primary crusher, as the first step of size reduction. It prepares the Jaw Crushers Powerscreen,Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size. Powerscreen jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts. About.

61· The particle size distributions for the five feed sizes are shown in Fig. 1.Due to the allowance for over and undersize in the naming of particle size fractions, the sizes d and D are not identical to the scalper slot widths.. Download : Download highres image (373KB) Download : Download fullsize image Fig. 1.Effect of Feed Rock Size Distribution on ,1022· The effect of the undersize in the feed upon the capacity of the crusher depends upon several factors. If the crusher is a primary breaker, and the

It can accept feed sizes up to 90 mm and has a stepless gap width adjustment from 030 mm. Depending on the sample material, it is capable of producing particle sizes down to 2 mm, resulting in a crushing ratio of 45. This versatile jaw crusher can be used in continuous pre and fine crushing processes, or in processline versions.The influence of feeder on the output capacity of jaw crusher,Therefore, strictly controlling the particle size of the raw materials is one of the most important prerequisites to ensure the normal operation of the jaw crusher. Practice has proved that when the maximum raw material particle size is 0.80.9 times the size of the feed inlet, the jaw breaker is not prone to jam and blockage. 2.

2023410· Crushing Stage. Rock crushing consists of three stages: primary, secondary, and tertiary. In the primary phase, large pieces of rock get broken down into smaller sizes to be fed into other crushers to reduce their size even further. Largecapacity crushers that can handle more sizable feed materials are typically used in this stage.Jaw crushers, Stationary Jaw crusher series — SRP,The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the feed characteristics (friction, gradation). WIDE TEETH (WT) For feed with a lot of fines; good wear resistance; can be used on both fixed and moving sides. SHARP TEETH (ST)

Also, generally speaking, as a Jaw Crusher size increases to accept larger feed particle sizes, the minimum crushed particle size will also increase. Sampling Jaw Crusher Sizes. Feed rates are dependent on the size of the crushed product. In sampling applications, these machines may have feed rates as low as several hundred ,