The extraction of aluminum from its ore and subsequent processing into finished prod ucts takes place in a series of successive operations, each largely independent of the other. How Aluminum is Produced Metallurgy for Dummies,Aluminum manufacture is accomplished in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the HallHeroult process of smelting the

The emission factors in Tables 11.241 and 11.242 are for the process operations as a whole. At most metallic mineral processing plants, each process operation requires Crushing in Mineral Processing,1226· The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm). This techniques

The aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide. About 90% of global bauxite Aluminum Ore Crushing Numerical Control Machine,1019· Aluminum ore primary crusher Here we recommend to you Zoneding Machine Jaw Crusher as aluminum ore primary crusher. There are both doubletoggle

112· Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses How to Get Aluminum from Bauxite,2023215· Bayer process steps for alumina production As the bauxite is found near the surface, it needs an openpit mining. Step 1 Crushing process The first

aluminum processing: Bayer process There are a number of alkaline, acid, and thermal methods of refining bauxite, clay, or other ores to obtain alumina. Acid and Mineral processing Wikipedia,Crushing, a form of comminution, one of the unit operations of mineral processing In the field of extractive metallurgy, mineral processing is the process of separating

The starting material for electrolytic smelting of aluminum is pure, anhydrous aluminum oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite. The process has been refined and improved since its inception.Bauxite Mining and Alumina Refining: Process Description and LWW,The bauxite ore contains aluminum trihydrate (Al(OH) 3). Alumina refining produces alumina (Al 2 O 3) from the bauxite ore, by exploiting the reversible reaction of the Bayer process 1–3: The reaction is firstly driven in the sodium aluminate (NaAlO 2) direction by the addition of caustic soda (NaOH) to bauxite. Bauxite residues are then

2023410· 1. Introduction. Decreases in mineral grades of known ore deposits, increasing global demand for commodity metals, greater operating costs of mining, and deeply buried deposits have stimulated interest in alternative mining technologies (Singh et al. Citation ).Conventional mining technologies are economically feasible for shallow Level Measurement for Crushers in Metal Ore Processing,As the material is brought into the crusher, it moves quickly through the crushing process. The fastmoving level must be monitored to determine when the material reaches a minimum level so that the next load can be started. The material is irregularly shaped and very dusty. The overall distance may be a far as 30 m (98 ft).

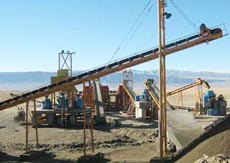

In the crushing process design of aluminum ore, GREATWALL Machinery adopts a jaw crusher, cone crusher, impact crusher, circular vibrating screen, and other equipment to form a closed cycle according to the rock characteristics, which can not only complete ore crushing and partial dissociation work but also can improve the subsequent grindingOverview of Ore Washing in the Mineral Processing Industry,217· Introduction. Ore washing can prevent the muddy material in the mudcontaining mineral raw materials from blocking the crushing and screening equipment. If the raw materials contain soluble useful

Through analysis, the TiO2 content of the ilmenite is 8.5%, the Fe content is 13.5% and the MgO content is 3.5%. In order to obtain good titanium and iron concentrates, after mineral processing test analysis, a mineral processing process of crushingcoarse grindingmixed preflotationfine grindingflotationmagnetic separationgravity separation was designed Gold Ore 7 Types and Extraction Methods Fruitfulchina,2023412· 7 Types of Gold Ore. 1. Freemilling Gold Ore. Freemilling gold ore is the most common type of gold ore, which is often found in openpit mines. It is characterized by the presence of visible gold particles that are easily liberated from the surrounding rock by crushing and grinding. The gold particles are usually small, ranging in size from a

2013312· Bauxite processing plant Unlike the base metal ores, bauxite does not require complex processing because most of the . Mining and Refining ? Process. 1821: Bauxite discovered near Les Beaux in southern France by Pierre Berthier: 1847: Armand Dufrénoy names the ore “beauxite” 1861: Henri SainteClaire Deville .Bauxite: The principal ore of aluminum.,Bauxite is the principal ore of aluminum. The first step in producing aluminum is to crush the bauxite and purify it using the Bayer Process. In the Bayer Process, the

2023410· Highcapacity crushing: With its powerful motor and large crushing chamber, our crusher plant is capable of processing large quantities of manganese ore quickly and efficiently. AdvancedProcess and installation for producing alumina trihydrate by ,A process for producing alumina trihydrate comprising an digestion step (26), a separation step (70), and a precipitation step (52) the separation step including: b1) pretreating a slurry from the digestion step by adding a flocculant to said slurry and mixing the flocculant and the slurry, b2) settling the resulting flocculated slurry in a

Crushing, a form of comminution, one of the unit operations of mineral processing In the field of extractive metallurgy, mineral processing is the process of separating Chapter 2. Production and Processing of Aluminum The ,The starting material for electrolytic smelting of aluminum is pure, anhydrous aluminum oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite. The process has been refined and improved since its inception.

The bauxite ore contains aluminum trihydrate (Al(OH) 3). Alumina refining produces alumina (Al 2 O 3) from the bauxite ore, by exploiting the reversible reaction of the Bayer process 1–3: The reaction is firstly driven in the sodium aluminate (NaAlO 2) direction by the addition of caustic soda (NaOH) to bauxite. Bauxite residues are thenFull article: Review of Fracturing Techniques (Microwaves, High ,2023410· 1. Introduction. Decreases in mineral grades of known ore deposits, increasing global demand for commodity metals, greater operating costs of mining, and deeply buried deposits have stimulated interest in alternative mining technologies (Singh et al. Citation ).Conventional mining technologies are economically feasible for shallow

As the material is brought into the crusher, it moves quickly through the crushing process. The fastmoving level must be monitored to determine when the material reaches a minimum level so that the next load can be started. The material is irregularly shaped and very dusty. The overall distance may be a far as 30 m (98 ft).Aluminum OreMaterial ProcessingMining Machine ,In the crushing process design of aluminum ore, GREATWALL Machinery adopts a jaw crusher, cone crusher, impact crusher, circular vibrating screen, and other equipment to form a closed cycle according to the rock characteristics, which can not only complete ore crushing and partial dissociation work but also can improve the subsequent grinding

217· Introduction. Ore washing can prevent the muddy material in the mudcontaining mineral raw materials from blocking the crushing and screening equipment. If the raw materials contain soluble usefulbauxite mining process Mining & Quarry Plant,2013312· Processing of Bauxite Ores To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to Bauxite mining process,Bauxite mning equipment used for If you need iron ore crusher,gold ore crusher,copper ore crusher or other mining machinery,you can contact us.We are professional manufacturer of mining

Through analysis, the TiO2 content of the ilmenite is 8.5%, the Fe content is 13.5% and the MgO content is 3.5%. In order to obtain good titanium and iron concentrates, after mineral processing test analysis, a mineral processing process of crushingcoarse grindingmixed preflotationfine grindingflotationmagnetic separationgravity separation was designed Gold Ore 7 Types and Extraction Methods Fruitfulchina,2023412· 7 Types of Gold Ore. 1. Freemilling Gold Ore. Freemilling gold ore is the most common type of gold ore, which is often found in openpit mines. It is characterized by the presence of visible gold particles that are easily liberated from the surrounding rock by crushing and grinding. The gold particles are usually small, ranging in size from a

The first step in producing aluminum is to crush the bauxite and purify it using the Bayer Process. In the Bayer Process, the bauxite is washed in a hot solution of sodium Physical Bauxite Processing: Crushing and Grinding of Bauxite,123· 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

2023410· Highcapacity crushing: With its powerful motor and large crushing chamber, our crusher plant is capable of processing large quantities of manganese ore quickly and efficiently. AdvancedProcess and installation for producing alumina trihydrate by ,A process for producing alumina trihydrate comprising an digestion step (26), a separation step (70), and a precipitation step (52) the separation step including: b1) pretreating a slurry from the digestion step by adding a flocculant to said slurry and mixing the flocculant and the slurry, b2) settling the resulting flocculated slurry in a